UpLift.ED

Ed - The home assistance robot by team UpLift.

Ed was developed as part of a university honours group project by Team Uplift, with the goal of assisting individuals with mobility challenges. Our brief was to design an assistive robot within a 10-week period. The solution we created, Ed, is designed to improve accessibility in the kitchen. Ed works in tandem with customised shelving units equipped with a ‘cake tin’ base. It can map out a kitchen area and identify shelving units using labelled markers. Through a mobile app, users can control Ed to open and raise drawers to counter level, making kitchen storage significantly more accessible for those with limited mobility.

Design

- AutoCAD: Used for designing the scissor lift, drawers, and custom handles.

- Webots: Used to build Ed and simulate the testing environments, ensuring accurate physics and functionality.

- Python: Utilised for Ed’s navigation system and movement controls.

My Role and Key Contributions

As a key contributor to the project, I played a central role in building the robot in Webots, designing test environments and troubleshooting integration issues. While other team members worked on components like navigation software, component integration and reporting, my main contributions included:

- Concept Development: I came up with the initial idea for Ed and the tailored shelving system and worked collaboratively to shape the overall design of the project.

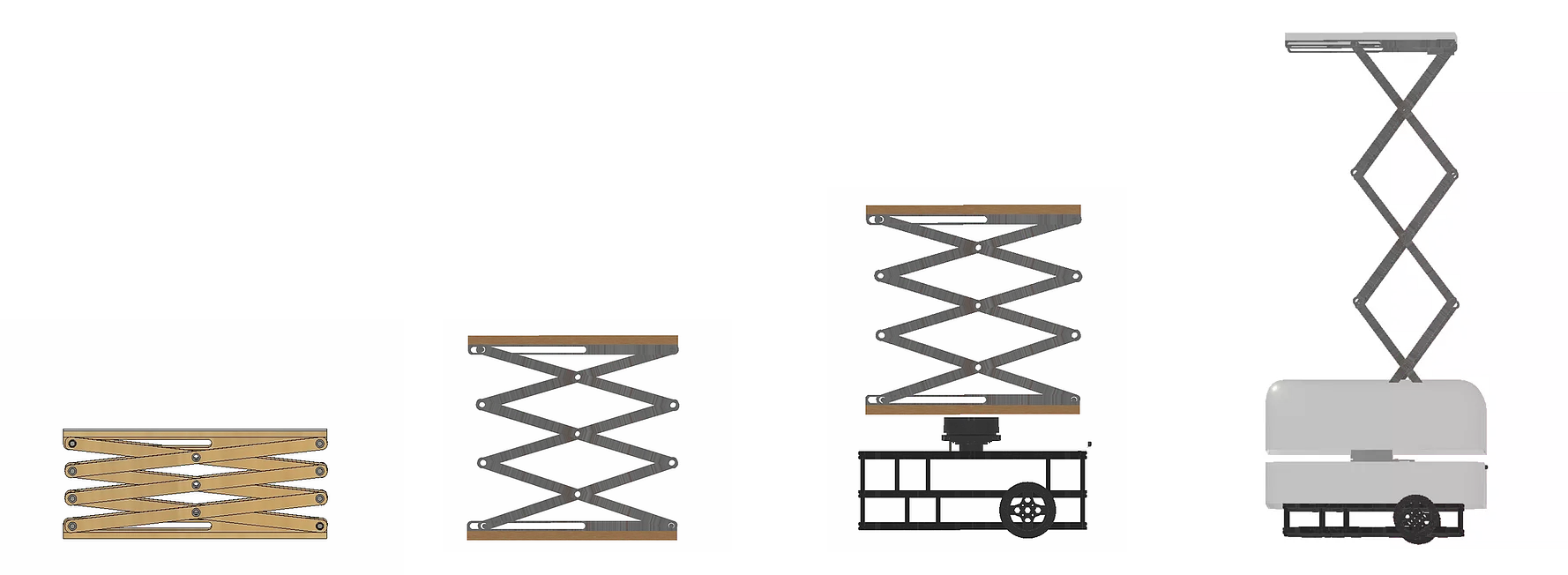

- Scissor Lift Mechanism: Collaborated with a team member experienced in CAD to design the scissor lift. I was responsible for assembling the robot within Webots and ensuring it accurately reflected real-world physics and functionality.

- Drawer Design & Custom Handles: Worked alongside the same team member to create CAD designs for the drawers and custom handles, then integrated them into the Webots simulation.

- Kitchen Testing Environments: Designed and built the simulated kitchen environments used to test Ed’s capabilities.

- Webots Troubleshooting: Served as the primary troubleshooter for Webots-related issues, ensuring smooth integration and functionality of the robot within the simulation.

Team Contribution

- Navigation Software : This team member focused on Ed’s navigation capabilities.

- Component Integration: This team member ensured seamless integration of all project components.

- Reporting and Presentation: This team member led our documentation and presentations.

Challenges & Solutions

Creating the Scissor Lift

Designing the scissor lift in Webots was incredibly challenging, especially since errors would not produce any messages — the lift simply wouldn’t function. Having no prior experience in robotics or Webots, I spent many hours learning how the software worked from scratch to create the scissor lift accurately.

After several failed attempts, I decided to take the process back to basics. Instead of attempting the full three-level lift all at once, I focused on building a single-level lift. Once this simpler version worked, it became much easier to scale it into the required three-level lift.

The biggest challenge was ensuring that all components, such as the motor, sliders and hinges were placed precisely. This precision was necessary to keep the lift perfectly balanced and allow smooth movement of all parts.

Integration Issues in the Testing Environment

Another major challenge arose when the robot, which had been created in a separate testing environment, began to fail upon being moved into the main testing environment. Fortunately, through the difficulties I faced while creating the scissor lift, I had become highly familiar with the Webots software.

Since there are limited resources available for Webots online, I relied heavily on trial and error, which greatly improved my problem-solving skills and proficiency with the software. This knowledge proved critical as I was able to quickly resolve the integration issues under a tight deadline.

Working Under Tight Deadlines

The project followed an agile methodology with two-week sprints which required the team to rely on each other to meet deadlines. For instance, it was essential that I completed the scissor lift by a specific date to allow the navigation team enough time to integrate their software before our final presentation deadline.

Meeting these deadlines was particularly challenging and we often worked long hours to ensure the project progressed smoothly. Despite the pressure, our team successfully delivered the required robot, reports and presentations on time.

Lessons Learned

The main takeaway from this project was learning to manage tight deadlines while balancing multiple responsibilities. Alongside this project, I had other courses to complete, which required careful time management to ensure I met all deadlines for both the team and my studies. Although it involved long hours, I successfully delivered on all commitments.

Communication was another key factor in the project’s success. Our team held productive meetings every two days to stay aligned, address challenges and discuss solutions. This regular communication kept us on track and ensured we met our goals.

I also learned to apply programming principles to robotics engineering. Initially, I attempted to build the scissor lift in one go which proved overly complex and unsuccessful. Recognising this, I broke the problem into smaller, manageable steps — starting with the simplest single-level lift and testing at each stage. This incremental approach was highly effective and shaped how I now tackle complex challenges in group projects.

Recognition

Our team achieved one of the highest grades in our year for the project. The Webots advisory for the course recognised the quality of our work and attempted to invite the creators of Webots to our online presentation session.